We have been seeing quite a few problems with the GM 2.2L and 2.4L engines. Mostly on model years 2005 through 2009. This engine is very common in the Chevrolet Malibu, Cobalt and HHR. As well as the Pontiac G5 and G6. This is the 4 cylinder. The problem I am going to talk about today is a check engine light and misfire codes.

Car maintenance can be a difficult task but luckily you can find the parts you need online for almost any repair job.

Check Engine Light

Now, there are many, many things that can cause an SES light. Anything from a loose gas cap to any number of failed sensors. But this particular problem is with a computer trouble code P0300. This is a general engine misfire. For a particular cylinder, the code would be P0301, P0302, P0303 or P0304, as the last number refers to which cylinder is misfiring. On a scan tool we can actually watch the cylinder misfire. This problem can be caused by a faulty spark plug, malfunctioning ignition coil or ignition module, a plugged or restricted fuel injector or an internal mechanical problem.

Engine Misfire

The problem we are seeing with this engine is the misfire on a warmed up motor, only at idle. If you press the gas pedal just a little, the fault goes away. There is also no problem at higher speeds or steady driving or accelerating. Normally we mechanics would first look for a vacuum leak. This would cause the problem at idle any any motor. When no vacuum leak is found, the ignition and fuel system components are tested and shown to be working properly, then the next step is to look into an internal mechanical fault.(See Pictures Below)

There are a few test that can be performed to test the overall health of the engine. First would be a cylinder compression check. That is done by removing the spark plugs, disabling the fuel injector and ignition systems, and cranking the motor over with the tool installed. We watch the gauge for several things. First, how high the pressure jumps on the first revolution, and then what is the highest reading after a few seconds of cranking. Cylinders are compared to each other looking at both these readings. This will show the difference, if any, of compression between cylinders. That can give an indication as to what cylinder to concentrate on. But since we are using a scan tool to watch live data stream, we know which to look closely at. A compression test can be a little misleading. Low total compression can be caused by worn piston rings, incorrect valve timing, or valve and seat problems. Depending on the condition, this test may not show any abnormal readings.

Compression Test

In this case, the compression on one cylinder is a little low. Squirting a little motor oil in the cylinder and running the test again shows no improvement. If it had, we would suspect worn piston rings, as the oil would have helped seal up the piston rings and raised the compression, which is not what is happening in this case.

So the next test on this 2.2L or 2.4L, which is much more comprehensive, in what is called a cylinder leak down test. This is a little more involved. This entails removing the valve cover, loosening the camshafts (this is an overhead cam engine) and removing the rocker arms (also called followers) to let the intake and exhaust valves come all the way up and seal the combustion chamber.

The the tools is installed to pressurise each cylinder with a regulated amount. What we do is look for a percentage of leaking of this pressure. A certain percentage of loss means there is a problem. So now we have to find what is leaking. Listening in several different places is what is needed to locate the bad part. Opening the throttle to listen for the leak in the intake side. Listening in the exhaust pipe will show a problem on the exhaust side. Either way, the cylinder head must be removed.

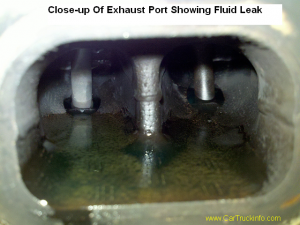

After removal, the valves and valve seats are inspected. A great test to find where the leak is, is to turn the head over and fill the combustion chamber with water, or even better, washer fluid. The blue color makes it easier to spot the leaking valve and or seat. See Pictures below.

The fluid is leaking past the exhaust valve seats and into the exhaust port. This is causing a sort of vacuum leak inside that cylinder. More specifically a lean condition. This is why there is a misfire at idle. Above idle, at faster engine RPM, there is no time for the cylinder to leak, so no engine misfire. The repair for this particular engine misfire is to replace the cylinder head and bad valves. This aluminum head is not repairable, so replacement is required.

Again, this problem is specific to the 2005 through 2009 2.2L and 2.4L. So if you are having an SES light and misfire or rough idle, be sure your mechanic does a thorough inspection and diagnosis to avoid guessing and replacing parts. A simple tune up or sensor is not going to fix this one.

Leave comments below or see these

Leave A Comment, Reply Or Ask A Question

48 Comments on "Check Engine Light Code P0300 On GM 2.2L and 2.4L"

I have that issue on a 07 malibu 2.2 did a compression test show up at 150psi to 152psi replace the worn out plus and 3 of the 4 coils had a circuit so replace all 4 and still have a random misfire code p0300 check the swap the ecu and nothing check the maf and voltage was voltage and continuity was good. I just can’t find thw issue.

My cobalt 2008 still having problems it was fixed on my recommendation, after reading that it may be a valve leak,the mechanic, refurbished the cylinder head, replaced what was necessary, now the light stays lit all the time, the engine runs fine, somebody out there has any idea what it could be, if you clear it stays off while engine is running, turn engine off and start it again, light comes back, thanks for any help.

Thanks a lot,it really explain just what happening with my cobalt 2.4 2008, took it to my mechanic, he has all the certifications to work an almost any engine, up to date , yet he can not find what is wrong with this car, he is a honest mechanic, so far he has replaced oxigen sensor 3 times did a good cleaned up of intake manifold , still after all those repairs trouble comes back, same thing , repairs still on warranty, I will mention to him this comment , and see what he says thanks again.

What’s causing the oil filter cap to blow off on my 2008 chevy Malibu 2.2L ecotech? I have replaced the old one the ring at the top new oil oil filter and I keeps blowing it off! Plz I need feed back asap

Replace the pcv valve or the whole valve cover because it’s integrated in the cover and is a diaphragm type pcv which tears and will lock in the pressure ,my problem was on a aveo and it caused my oil cooler to bleed out the oil cooler ! (It’s path of least resistance)

I’m having same problem with 2007 Saturn ION 2.2 L . JUST bought car and basically got screwed because guy took to his mechanic has spark plugs and coil pack replaced so I know his mechanic had seen there was still a problem with the car and guy failed to disclose that information. Well check engine light came on started missing mainly at idol when I excelerate it stops. Had compression check and showed cylinder 3 has low compression. My mechanic did several tests to conclude probably bad cable. Hopefully that’s the only thing wrong. I haven’t had a car for over 5 years now and had saved money to get another and got this. Found out also has several recalls on it. Does anyone know if fuel pump module is still on recall? I know it definitely has ignition problem I can pull key out with it being on off position. My airbag light is also on. I’m trying to find out about the Tamara airbag recall because I’m not seeing it in GM’s sight. If anyone knows about these please let me know. Thanks

My fix (below) was for a 2006 Chevy Cobalt 2.2 L

The fix was ignition module and coil assembly shipped as one complete unit from rock auto at a cost of about $150.

1991 Toyota Camry … i am experiencing a usage of too much gas intake from my car .. how do i fix this problem

Can’t. Get a video. On how to remove a cylinder. Head off a 2006 chevy malibu 2.2enginei took all the bolts out. Will not budge

Spun main bearing

I have a 92 Buick century,4 cylinder that misses, back fires, and has no power gong up hill, it will get downc to 30mph sometimes and sounds horribly.When I figure out,I will post on what the problem is

I was told today this will cost me

$2500 to fix today. 50k miles! WTF. looks like a manufacturing defect to me,

I recently bought a Saturn Ion 2006 with 187K. The check engine light came on a week after purchasing. I then noticed a blue color smoke come from the exhaust after starting it, just happened once. Today I pumped gas and was leaving the station when my car started to bog down and idle hard. I turned it off and tried again. A few hours later, it started to feel like the gas pedal wasn’t working right, then the reduced power light came on. I turned it off for 10 secs and tried again… didn’t help. It seems to run a lot harder and the accelerator isn’t getting better, help please!!!

I had thesame problem few months ago with my saturn vue 2.2l 4 cylinder.

i was driving on the highway, suddenly i got a reduce power light and my gas pedal was no more under my

control. And the vehicle was only making 60 kilo/ hr. I couldn’t accelerate to pass 60k

When i arrive at home, i immediately open up the hood to listen for any kind of mechanical noise. From

observation as this engine was running each time I press the gas pedal there was a noise from the throttle Body

then I removed the air filter cover to the throttle body exposing the throttle plate. then l stared the

Engine again press on the gas pedal the noise became more louder. The Throttle plate was too loose.

For quick fix I went to the scrap yard pickup one throttle body position sensor. I install it Boom there you go .

Now is running perfactely fine

Catalytic converter is plugged if you haven’t found out yet

I bought a one owner 2006 Saturn Ion with 188K. It’s a nice well taken care of car, I really liked it in the first few weeks. Then I started noticing problems. First, the check engine light came on, then the air bag light, I had an oil change and reset the computer. Now, each time I put in gas, once I start the car it will seem like it’s bogging down and will idle hard. I will push the accelerator to keep it from dying. Today I was leaving the gas pump when I pushed the accelerator as usual, but it acted like it wasn’t getting gas at all. A few hours later later, I noticed the accelerator was hard like it wasn’t working right. That’s when the reduced power light came on. I done the 10 second test like the manual said but it came back on when I turned the engine on again. It stays on now, it seems like the accelerator isn’t getting better. It runs rough too.

Catalytic converter

I’m a little bit confused. I see the article says 2005 to 2009 is the issue motors, but someone in the comments asks about a 2010 motor and you say refer to the article, so is the 2010 motor also an “issue”, in other words where does it end OR does it. I am looking at buying a 2010 HHR, but now I’m thinking maybe I shouldn’t? Please let me know ASAP anyone out there as I have a limited time to act on this vehicle… allen@tennesseeland.com

Ok, REALLY NEED HELP , I HAVE A 2010 HHR LT WITH TROUBLE CODES PO302 AND P0300. I HAVE PUT NEW SPARK PLUGS IN , A NEW COIL, AND COIL WIRE CONNECTOR , EVERY THING THE DEALER SAID NEEDS TO BE DONE FIRST TO RULE OUT ANY OF THOSE POSSIBLE ISSUES. I STILL HAVE THE SAME CODES POP UP AFTER A FEW DRIVES AND IT SEEMS TO COME BACK WHEN THE CAR IS AT IDLE, PLEASE ANY HELP WOULD BE GREAT , I AM RUNNING OUT OF IDEAS.

Read the article above. It explains what is wrong with your car. You need valve and cylinder head work.

Okay Mr. Parts changer . Then what will you change , when it still runs like Donkey dung .

2008 Chevy Cobalt 2.2L – Did all the normal steps; moved sparked plugs, ignition modules & injectors to another cylinder and still a misfire on #4. Only thing replaced so far was the o-rings on the injectors. Checked for vacuum leaks and there are none.

After the ignition and power steering recall replacement recently I had to replace the TCM after the transmission started acting up . There was a flutter shifting into overdrive and it wouldn’t stay unless I gave it a little kick. Since I didn’t have the time to work on it, I took it to transmission shop. The owner told me he was getting weird readings after forcing the TCC solenoid into overdrive. The trans was staying in overdrive, which meant no leaks in o-rings. Instead of trying to stick me with an $800 bill to replace the TCC solenoid, I suggested we get a TCM from the junkyard for $40. He couldn’t believe it solved the problem. I’m a tech guy and deal with computers all the time, however, they are little different on cars.

Since there is no Ignition Control Module on this car and the plugs are fired by the ECM, I’m wondering what your thoughts are on that being the problem given the background of the TCM issue. An ECM from the junkyard from the same model car is $50. The ECM would need to be flashed with the correct VIN, if it solved the issue.

Next step would be the compression test

Any thoughts?

Before you go spending lots of time and money….. change your AIR FILTER.

Just got my 2009 HHR fixed and here is what it was. Started surging, Service Engine Light came on and gave a P01100 code for Intake Sensor on front of engine so I bought new one and it ran good for about a week. Then Service Engine Light came on again and gave code P01100 again but lead to Intake and Exhaust Solenoids on top of engine. Bought and installed those. Ran fine for a day or two then while on a trip far from home at a station it started and killed. It would not keep running long enough to drive it. It was obviously missing. Had code reader with me and it gave codes P0101 and P0300. The P0300 is apparently a catch all code that GM must use for many things so it was very hard to pin it down. It did say something about “Air Flow or MAF” on my code reader. With just enough knowledge of auto mechanics to be dangerous I thought maybe it is the Air Filter since I had never changed it. Remember car is barely running and coughing and stumbling to even drive. I bought a new air filter ($12) and presto….. all problems solved. I had to clear codes manually but car is running like new.

Like I said I just got done but I have all the faith in the world that the problem is fixed.

Hope this info is helpful to others.

I have a 2005 cobalt with a po300 code reading ! My car has a lack of power and you can smell it flooding . Can you give me any advise onto the problem?

Hi,

When you wrote..” replace cylinder head and bad valves” you mean replace Cilinder Head Gasket & bad valves?

Thanks.

No, I think they mean the cylinder head itself needs to be replaced.

2006 Saturn ion P0300 bad idling and misfiring bad under load acceleration also good at steady speed

any thoughts on what to look at next, replaced plugs swapped coil and checked all electrical connections

I have a 2001 grand am 2.4L that recently got new piston rings and timing kit installed as well as all gaskets, coil housing, coil packing, spark plugs, and even fuel injectors, as well as fuel pressure regulator. not too long after I got a PO300 code and I cant figure out, could it be timing if so how can I check the timing. or MAP sensor it does not have a MAF sensor, it idles rough a little bit after start could you help?

for pontiac g5 if engine lights comes on and code reader says p0010 , it means chassis and body ground r not properly connected or grounded ….

2009 hhr 300 code. Shows up only when I start the car. Puff of smoke from tailpipe.

did i just leave 1

2005 malibu, 2005, when engine is warm and not all the time, but temp guage just rises up past half, the engine will flutter at exhaust, loss of power, the cat was replaced. what do you think

You may have a coolant leak causing and engine misfire.

i have an 2005 chevy cobalt and i was told it has low compression and this is after someone put something in my gas tank. The dealer ship is saying its probably my engine but they only looked at it for 30 mins. They claim there is nothing in my tank or lines. my car will start but just stalls right back out unless you hold the gas down.so is the dealership right or is it something other then my engine.

It would have to be something very bad in your gas to cause l;ow compression= very unlikely. Possibly diesel fuel in the gas could have caused that.

i have a 2005 cobalt and i was told it has low compresion after someone put something in my gas tank and the dealer ship is a joke. what is the problem. the dealer ship is jumping right to putting a new engine in. is their a cheaper fix

Have a misfire on 1st cylinder..after I’ve changed the spark plug it went away for a few days but the check engine light came back on givong the same error. .it does it when its idle amd than when I take off..I’ve also changed seals suspecting a leak to the spark plug. .didn’t help.